Tshiab Lotoke Forged Steel Pob Valve Catalog

POB VALVE DESIGN FEATURE

Pob li qub yog siv dav hauv roj av refining, tshuaj, ntawv ua, tsev muag tshuaj, zaub mov, dej fais fab, nroog, hlau thiab lwm yam lag luam. Ntawm lawv, sulfur-resistant series pob li qub yog tshwj xeeb tshaj yog haum rau ntev -kab raj xa mus rau siab -corrosion natural gas nrog sulphuret hydrogen nruab nrab thiab ntau impurities.

TXOJ CAI NYIAJ

Yuav kom ua tau raws li cov kev xav tau sib txawv ntawm cov neeg siv khoom, peb muab ob lub pob valve, tag nrho bore thiab txo qis pob valve. Lub channel puab txoj kab uas hla ntawm tag nrho cov bore pob li qub yog raws li nyob rau hauv lub puab txoj kab uas hla ntawm pipeline, uas yuav tsis tau tsuas yog txo cov dej tsis kam, tab sis kuj pab txhawb kev tu cov kav dej.

Cov dej tsis kam ntawm lub caj dab bore pob li qub yog tsawg dua li ntawm lub ntiaj teb valve nrog tib lub caliber thaum nws qhov hnyav yog 30 feem pua sib dua li pob li qub nrog tib lub caliber. Yog li ntawd, nws tuaj yeem txo cov nqi tsim khoom thiab tus nqi, thiab yog siv dav heev.

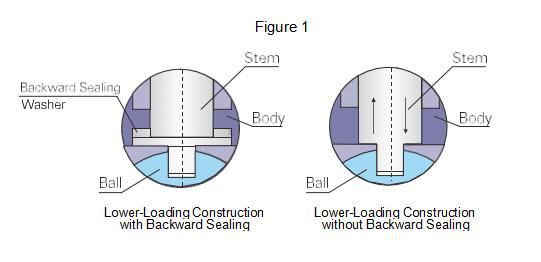

BL .OW - OUT PROOF STEM Lub qia yog rub tawm, nrog nws cov txheej txheem sib khi rov qab nrog sealing gasket. The force of inverted sealing structure will increase while the medium pressure in the valve cavity increases, to ensure the sealing effect of the stem. In case of abnormal pressure increasing of the valve cavity, the stem won't be impacted out. The flr is designed with proper V- -shaped structure, which can effectively convert the medium pressure inside the valve cavity and the locking force of outer gland into the sealing force of stem (Figure 1). |  |

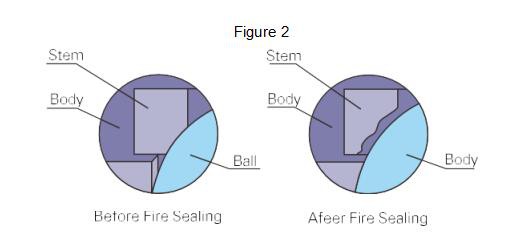

FIRE SAFE SEALING According to the user's requirement, the ball valve can be designed with fire-resistant structure. In case of a fire and the sealing ring is damaged, every sealing part of the ball valve can form the structure of metal-to-metal hard seal, which can prevent the spreading of both the media and fire (Figure 2). |  |

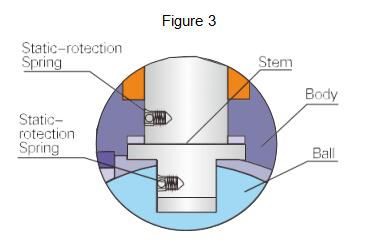

STATIC- KEV TIV THAIV Lub pob valve tuaj yeem tsim tau zoo li qub - tiv thaiv kev tsim kho raws li qhov xav tau, piv txwv li, mounting conductivespring ntawm lub ntiaj teb lub cev thiab qia, los yog nruab nrab ntawm qia thiab lub cev. Nyob ntawd tom qab qhov static engendered thaum lub sij hawm qhib lub valve tuaj yeem ua rau cov kav dej tom qab lub ntiaj teb dhau los ntawm pre - teeb tsa qhov chaw zoo li qub kom tshem tawm qhov zoo li qub. Tus qauv tsim ua haujlwm los tiv thaiv qhov hluav taws xob nruab nrab los ntawm hluav taws kub zoo li qub- tawm tsam rau kev nyab xeeb ntawm lub cev.(Raws li pom hauv daim duab 3) |  |

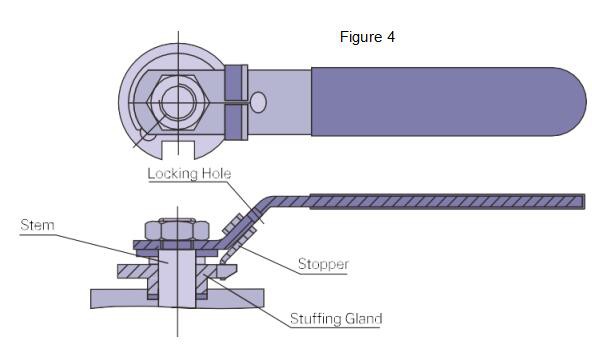

INTERL OCKING Device Rau li qub installdl sab nraum zoov, cov uas tiv thaiv kev ua haujlwm tsis raug tsis yog - cov neeg ua haujlwm thiab cov li qub, ntawm qhov uas ollision ntawm nws qia nyob rau hauv qhov kev vibration hnyav heev yooj yim ua rau kev ua haujlwm tsis raug, lub qhov rooj xauv tuaj yeem teem rau hauv txoj haujlwm qhib lossis kaw tag nrho. thiab lub xauv tuaj yeem siv yog tias xav tau, rau lub hom phiaj ntawm kev pov hwm kev nyab xeeb (Daim duab 4). |  |

2 PCS FORGED STEEL BALL VALVES 800L .B/1500L ,B

APPLICATION SPECIFICATIONS 1. Design and manufacture conform to BS5351 MSS SP-118 2. Connection ends conform to: 1) Scoket welded xaus raws li ANSI B16.11 2) Cov ntsia hlau xaus ua raws li ANSI B1.12.1 3).Butt-welded xaus raws li ANSI B16.25 3. Test and inspection conform to API598 4. Materials conform to ANSI/ASTM |  |

VALVE Lub Cev Muaj Zog RATING Chav Kawm 800, Max 1920 psig @ 100 degree F Chav Kawm 1 500, Max 3600 psig @ 100 degree F |  |

2 PCS FORGED STEEL BALL VALVES 800LB / 1500LB

| APPLICATION SPECIFICATIONS 1. Tsim thiab tsim ua raws li BS5351 MSS SP-118 . 2 Kev sib txuas xaus ua raws li: 1). Scoket welded xaus raws li ANSI B16.11 2). Ntsia hlau xaus raws li ANSI B1.12. 1 3). Butt-welded xaus raws li ANSI B16 25 3. Kev kuaj thiab tshuaj xyuas raws li API598 4. Cov ntaub ntawv raws li ANSI/ASTM |

| VALVE Lub Cev Muaj Zog RATING Chav Kawm 800, Max 1920 psig @ 100 degree F Chav Kawm 1 500, Max 3600 psig @ 100 degree F |

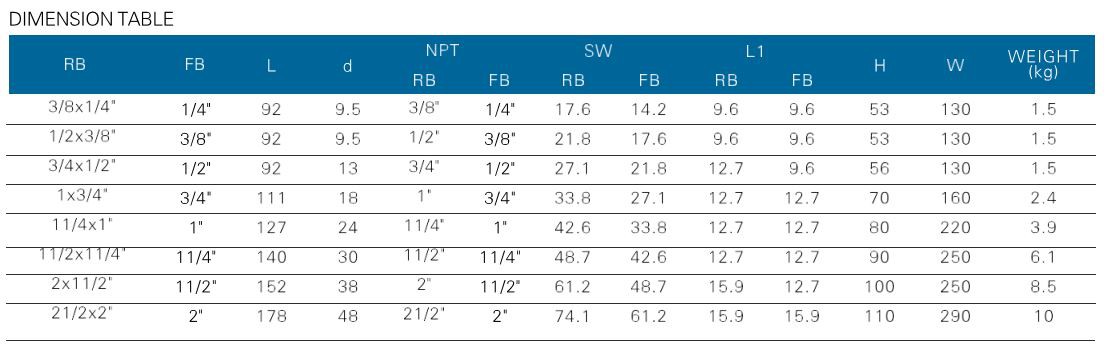

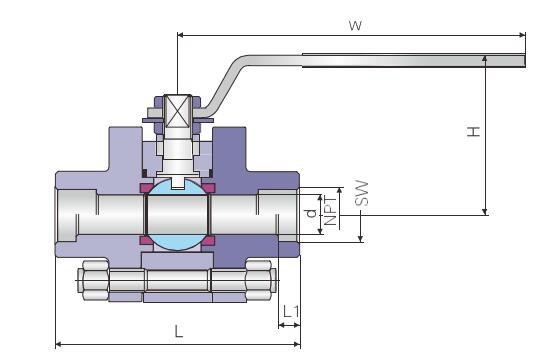

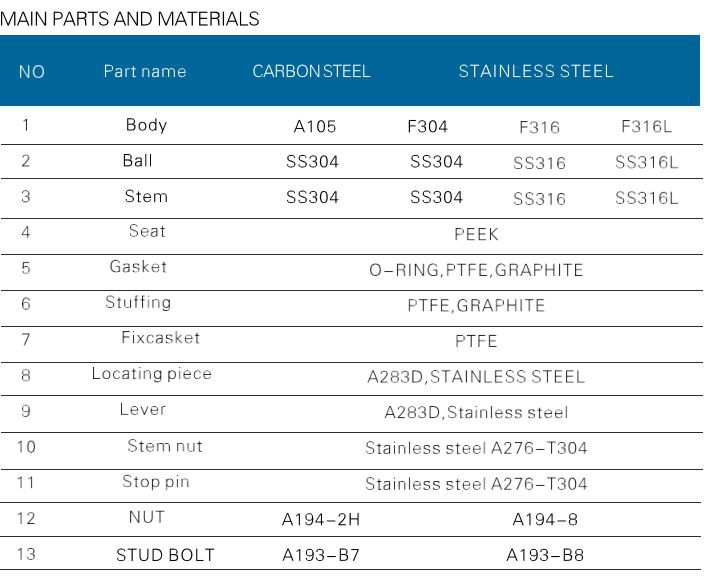

3PCS FORGEDSTEEL BALL VALVES 2500LB

APPLICATION SPECIFICATIONS 1. Tsim thiab tsim ua raws li BS5351 MSS SP-118 2 Kev sib txuas xaus ua raws li: 1). Scoket welded xaus raws li ANSI B16.11 2). Ntsia hlau xaus raws li ANSI B1.12. 1 3). Butt-welded xaus raws li ANSI B16. 25 3. Kev kuaj thiab tshuaj xyuas raws li API598 4. Cov ntaub ntawv raws li ANSI/ASTM |  |

VALVE Lub Cev Muaj Zog RATING Chav Kawm 2500, Max 6000 psig @ 100 degree F |  |

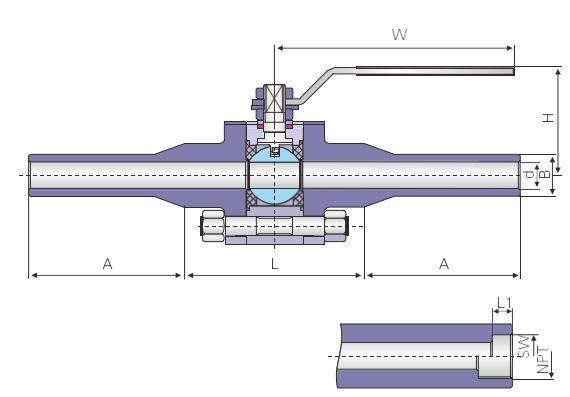

Nrog 100MM Yeeb Nkab Xaus 3 PCS FORGED STEEL BALL VALVES 800LB -1500LB

| APPLICATION SPECIFICATIONS 1. Tsim thiab tsim ua raws li BS5351 MSS SP-118 2 Kev sib txuas xaus ua raws li: 1). Scoket welded xaus raws li ANSI B16. 11 2). Ntsia hlau xaus raws li ANSI B1.12.1 3). Butt-welded xaus raws li ANSI B16. 25 3. Kev kuaj thiab tshuaj xyuas raws li API598 4. Cov ntaub ntawv raws li ANSI/ASTM |

| VALVE Lub Cev Muaj Zog RATING Chav Kawm 800, Max 1 920 psig @ 100 degree F Chav Kawm 1 500, Max 3600 psig @ 100 F |

Cim npe nrov: tshiab lotoke forged steel pob valve catalogue, Tuam Tshoj, manufacturers, hoobkas, customized, lag luam wholesale, nqe, pheej yig, Tshuag, kev muag, dawb qauv

Xa kev nug